Cheap Silicon Steel Core Line Step Lap Electric Steel Lamination Cut To Length Machine

- $80000.00 /set

- 1 set

- Zhu Tang (Suzhou) Technology Co., Ltd.

- Jiangsu, China

- Mr Jack Liao

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Working voltage: | Max 1500-3000N.M; |

| Showroom Location: | None; | Warranty of core components: | 1 Year; |

| ITEM NAME: | CNC double shear and double punch cross cutting machine; | Warranty: | 1 Year; |

| Video outgoing-inspection: | Provided; | CNC System: | PLC; |

| Weight (KG): | 8000; | Applicable Industries: | Machinery Repair Shops,Manufacturing Plant; |

| Place of Origin: | Jiangsu, China; | Thickness: | 0.23-0.35mm; |

| Width Tolerance: | ≤±0.1mm; | Port: | Shanghai; |

| Application: | mainly for shearing and cutting iron cores in transformer; | CONTROL MODE: | CNC CONTROL; |

| Decoiler Loading: | 2000; | Packaging Detail: | Seaworthy packing; |

| Cutting Width(mm): | 40 - 400 mm; | Brand Name: | Zhutang; |

| FACTORY TYPE: | transformer automatic rolling machine manufacturer; | Model: | HJJ400; |

| Key Selling Points: | Famous brand PLC; | Machinery Test Report: | Provided; |

| Marketing Type: | Ordinary Product; | Feeding Speed(m/min): | 0 - 120 m/min; |

| Cutting Length(mm): | 350 - 9999 mm; | Payment Terms: | L/C,T/T; |

| Pay-off speed: | 0-100m/min; | Condition: | New; |

| Supply Ability: | 100 Sets per Year; | Width: | 40-410mm; |

| Cutting Thickness (mm): | 0.2 - 0.35 mm; |

Cheap Silicon Steel Core Line Step Lap Electric Steel Lamination Cut To Length Machine

Introduction

Cheap Silicon Steel Core Line Step Lap Electric Steel Lamination Cut To Length Machine HJX400 is used to shear, punch, and notch iron core sheet to makes fully inclined seam, half inclined seam and straight seam transformer iron core overlapping sheet, which can be used in small and medium sized transformer. Silicon-steel sheet coil material is punched and sheared as per preset sheet shape and size, and the finished sheets will be sorted and put in order at the end of the production line, then they can be laminated.

The decoiler adopts hydraulic expanding tight and electric inversion. The feeder is driven by servo motor, and is provided with length measuring device.

The punch unit includes a V-type punch and a set of cutters, punching and shearing are driven by a servo motor, this servo motor is longitudinally fixed and breadwise moved to drive; a hole punch and a set of punch dies, punching and shearing are driven by a servo motor, this servo motor is longitudinally and breadwise fixed, the size of the punch dies depends on customers’ option.

Shearing machine unit includes two metre cutting shearing machines, two sets of cutters,among them, Shear 1 is an angle adjustable,that is to say it can be fixed in a 45°or 90° working position, shearing is driven by servo motor. Depiler and sorting machines include depiler and pressing material device.

Our product model includes HJJ400, etc.

Main Components

1.Two-end decoiler (hydraulic expanding tight,electric inversion)

2.Slopping feed device

3. Feeder (driven by servo motor, length-measuring device)

4. Punch unit

5.Shearing machine unit

6. Outlet platform

7. Depiler and sorting machines

8. Catching material machine

9. Whole-line width adjusting system

10.Pneumatic system

11. Electric control system control cabinet and console

Technical Parameters

Typical standard specifications of HJJ400 are shown below, however these can be modified according to your requirements.

|

Roll Material Width Tolerance: |

≤±0.1mm |

|

Roll Material Burr Length: |

≤0.03mm |

|

Roll Material S Degree Tolerance: |

single direction less than 0.1mm in 1000mm |

|

Roll Material Wave Degree: |

≤15mm/1000mm( span more than 1000mm, height less than 15mm) |

|

Sheet Thickness: |

0.23~0.35mm |

|

Sheet Width: |

40~410mm |

|

Sheet Length: |

350~2500mm |

|

Punching Hole Dia. |

10mm~24mm |

|

Punching Hole Position: |

can be bidirectional offset along the center line |

|

V-type Punching Eccentricity(along the center of the sheet): |

±30mm |

|

Speed of Feeding: |

0~100m/min |

|

Power: |

15Kw |

|

Working Voltage: |

380V |

|

Operating Direction: |

Left line |

Figure 1:CNC Cutting Machine For Transformer Core HJJ400’s full view

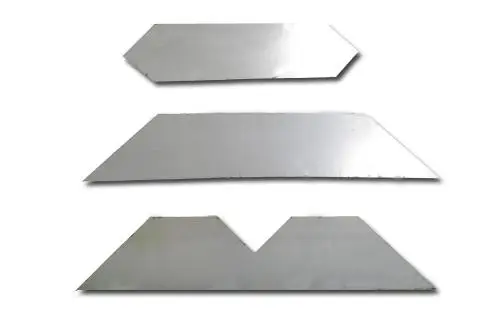

Figure 2:CNC Cutting Machine For Transformer Core HJJ400's cut product

|

|

|

|

|

|

|

1) Q: Are you manufacturer or trading company?

A: We provide technical support online as well as overseas services provided by our skilled technicians.

Zhu Tang (Suzhou) Technology Co., Ltd.

Other Products

-

Automatic transformer silicon steel core cut-to-length cutting line$90450.00 - $92300.00 / set

Automatic transformer silicon steel core cut-to-length cutting line$90450.00 - $92300.00 / set -

Programmable Transformer Silicon Steel CNC Cut to Length Line$50000.00 / set

Programmable Transformer Silicon Steel CNC Cut to Length Line$50000.00 / set -

CNC Transformer Silicon Iron Cut To Length Line$50000.00 / set

CNC Transformer Silicon Iron Cut To Length Line$50000.00 / set