New product T962A reflow soldering furnace special economical wave peak reflow soldering furnace T-962A for pcb soldering

- $373.46 / 2 - 29 sets

$348.58 / 30 - 49 sets

$323.67 / 50 - 99 sets

$298.77 / >=100 sets - 2 sets

- Shanghai Sihao Machinery Equipment Co., Ltd.

- Shanghai, China

- Mr Marketing VEVOR

| Core component warranty: | 1 year | Video shipment inspection: | if |

| Local service location: | not any | Packaging Details: | carton |

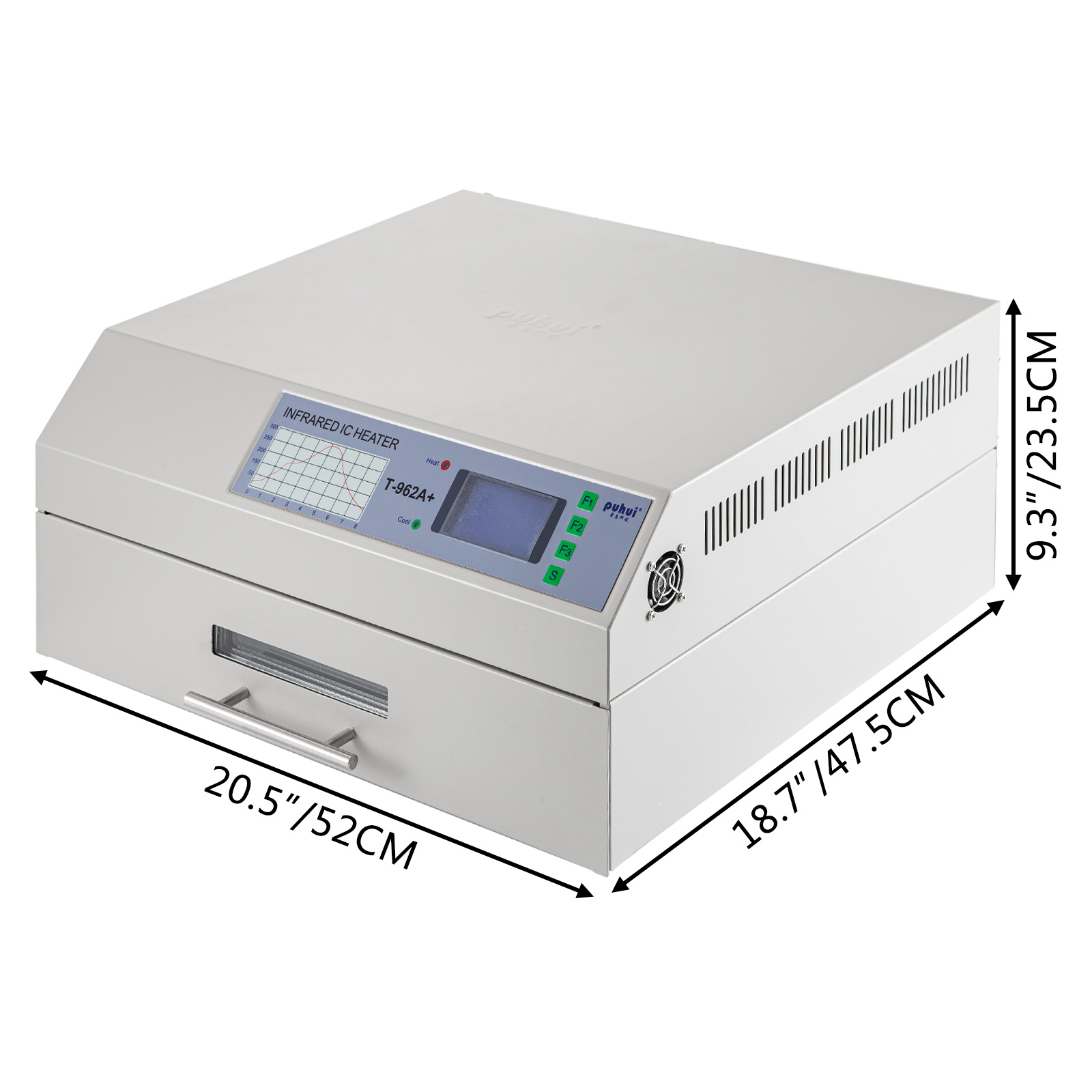

| Effective welding maximum area: | 370 x 450 mm (14.5 x 17.7 inches) | aspect: | 52cm*47.5cm*23.5cm |

| Mechanical test report: | if | port: | Shanghai |

| power supply: | AC110V/60Hz | Core components: | / |

| Supply capacity: | 5000 sets per month | brand: | four good |

| cycle: | 1~8 minutes | Main selling points: | easy to operate |

| Applicable industries: | Household, Energy & Mining, Other | After-sales service provided: | Video technical support, online support |

| type: | reflow soldering | After warranty service: | Video technical support, online support |

| Origin: | China | usage: | Printed circuit board soldering |

| Infrared reflow oven model: | T-962A+ | Certification: | CE certification |

| Marketing Type: | normal product | Nominal Duty Cycle: | 100% |

| rated power: | 2300W | temperature range: | 0℃-350℃ |

| Weight (kg): | 20.00 kg | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Health status: | new | Warranty: | 2 years |

| Voltage: | AC110V/60Hz | Showroom location: | not any |

New product T962A reflow soldering furnace special economical wave peak reflow soldering furnace T-962A for pcb soldering

T962A+Reflow Soldering Machine

The reflow soldering machine has a large maximum area for infrared soldering, effectively reaching: 370 x 450 mm. Thermal cycling accuracy is maintained by closed-loop microcomputer control of infrared heaters, thermocouples, and circulating air. This machine can weld most small parts of PCB, such as CHIP, SOP, PLCC, QFP, BGA, etc.

· Fast infrared radiation

· Large welding area

· Smoke outlet

· LCD screen

|

Specification · Infrared Reflow Oven Model: T-962A+ ·Rated power: 2300W · Maximum effective welding area: 370 x 450 mm (14.5 x 17.7 inches) Power supply: AC110V/60Hz · Temperature range: 0°C-350°C · Cycle time: 1~8 minutes Rated duty cycle: 100% |

|

|

Package Contents · 1 x T-962A+ reflow oven |

|

good performance; good performance

The reflow soldering machine adopts fast infrared radiation, smooth air circulation, accurate and uniform temperature. The parameters for eight (8) welding cycles are predefined. Thermal cycling accuracy is maintained by closed-loop microcomputer control with infrared heaters, thermocouples and circulating air. |

|

|

Large welding area

370 x 450 mm wide working area, thus making it able to work in different working conditions, making it the all-in-one device you want, large welding area for high efficiency. This greatly increases the range of use of this machine, making it an economical investment. |

|

excellent smoke vent

This efficient cooling system, including a smoke exhaust, is designed to guarantee rapid cooling of the product. At the same time, it provides the low temperature required for PCB board release. Therefore, the process you need can be completed safely and efficiently. (not including piping) |

|

|

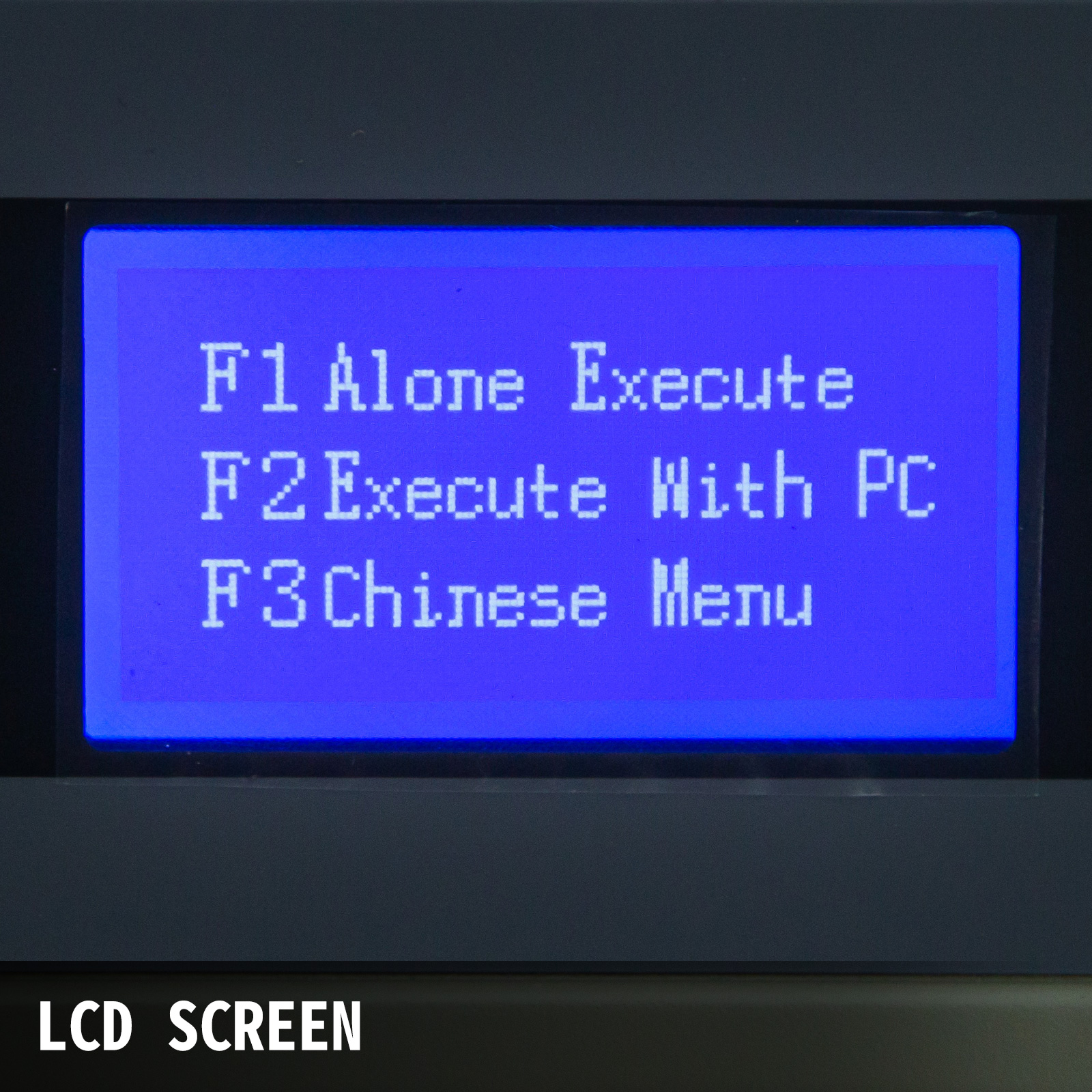

LCD screen

Complete visual operation through high-quality LCD screen. The welding cycle is selected through the keyboard, and the progress is displayed on the T962A+. |

|

automatic control

Fully automatic microcomputer control. From preheating, soaking, reflow to cooling, the whole soldering process can be done automatically. |

|

|

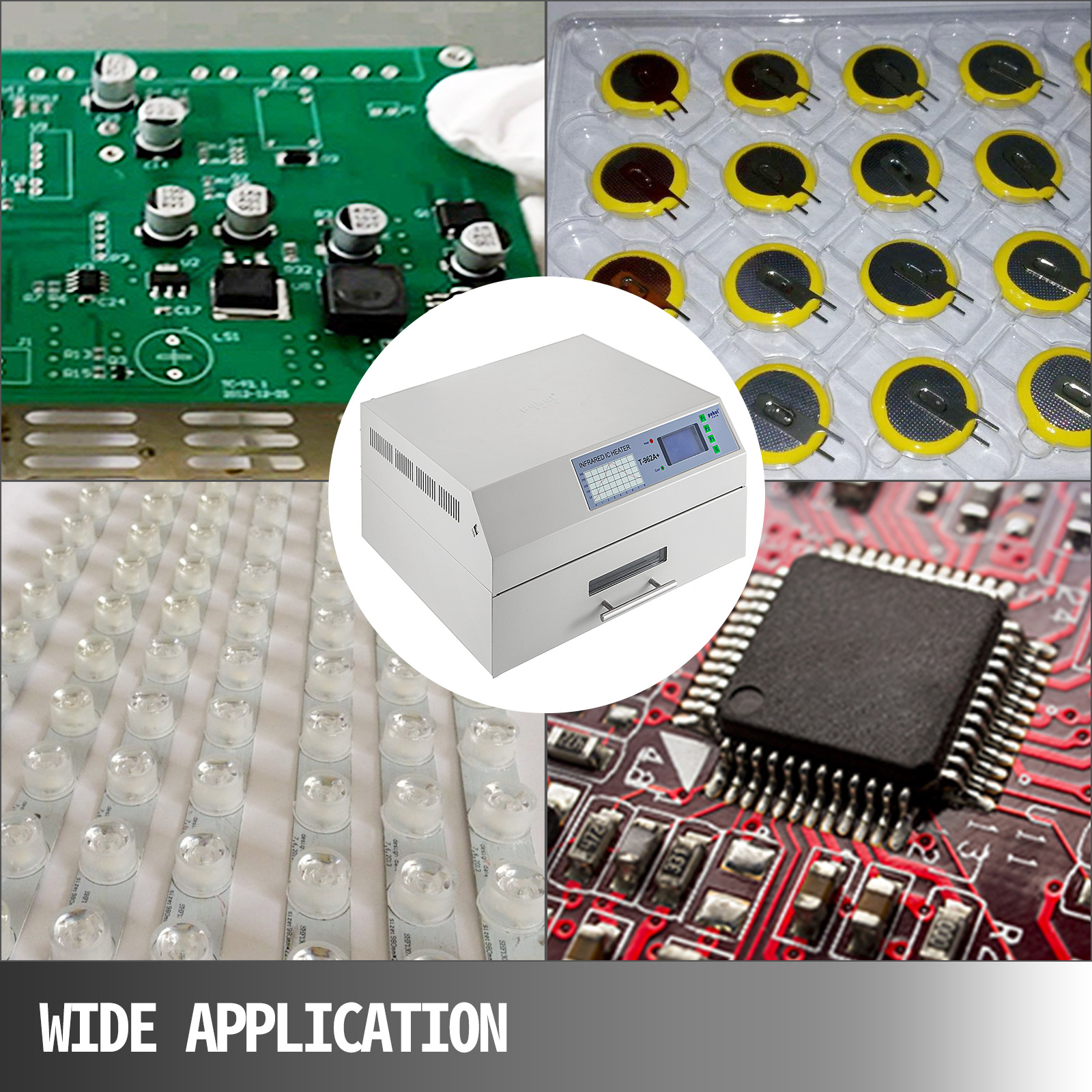

Wide range of applications

This infrared reflow oven can be used for glue curing, circuit board thermal aging, PCB maintenance, etc. It can also solder single and double PCB boards in various packaging forms such as CHIP, SOP, PLCC, QFP, and BGA. |

· [Wide Soldering Area]- 370 x 450 mm wide working area, which enables the reflow oven to work under different working conditions, making it the all-in-one device you want. The welding area is large and the efficiency is high.

[8 kinds of temperature waves to choose from] - This T962A+ SMD reflow oven can provide 8 kinds of stored temperature parameter waves as options, and has mobile heating and cooling functions; the whole soldering process is automatically completed and easy to use.

· [Efficient Cooling System]- The smoke exhaust port ensures the low temperature required for rapid cooling of the product and release of the PCB board. Therefore, this reflow soldering station provides you with high efficiency.

· [Easy to use]- Speed, time and temperature data are integrated into one LED display for easy visual observation. The external operation panel of the SMT reflow oven avoids excessive temperature inside the panel and ensures stability and safety.

· [Wide application]- T962A+ reflow soldering machine can solder most small parts of PCB boards, such as CHIP, SOP, PLCC, QFP, BGA, etc. The ideal rework solution from single runs to on-demand low-volume production.

Other Products

-

Best 500m Laser Level with Tripod Level Auto Leveling Laser Level Tool

Best 500m Laser Level with Tripod Level Auto Leveling Laser Level Tool -

Digital multifunctional fully automatic rotating laser level rotating red laser level rotating green laser$170.00 - $195.00 / set

Digital multifunctional fully automatic rotating laser level rotating red laser level rotating green laser$170.00 - $195.00 / set -

Brand New 16" X 16" Screen Printing Flash Dryer Adjustable Stand T-Shirt Curing With Temperature Display$66.00 - $93.00 / set

Brand New 16" X 16" Screen Printing Flash Dryer Adjustable Stand T-Shirt Curing With Temperature Display$66.00 - $93.00 / set -

Hot sale digital multifunctional fully automatic rotating laser level rotating red laser level rotating$170.00 - $195.00 / set

Hot sale digital multifunctional fully automatic rotating laser level rotating red laser level rotating$170.00 - $195.00 / set